Ganero brake lines

We live by the ideal that a product is not worth making unless you can improve and make it better. DURING THE R&D STAGEs, many components, materials and techniques were tried and the best goes on to form Ganero. PTFE inner core by Teflon or Daikin were used in these brake lines. We also applied vacuum metalizing, a coating posseses a far higher resistance to wear than traditional anodizing.

Supplied by industrial leading manufacturer with the following applicable standard.

US DOT FMVSS 106, SAE J1401, ADR 7/00, TSD 106, GB 16897, and JIS D 2601: 2006 (JSAE/JSA) TUV ISO 9001:2015

Passionately assemble in-house.

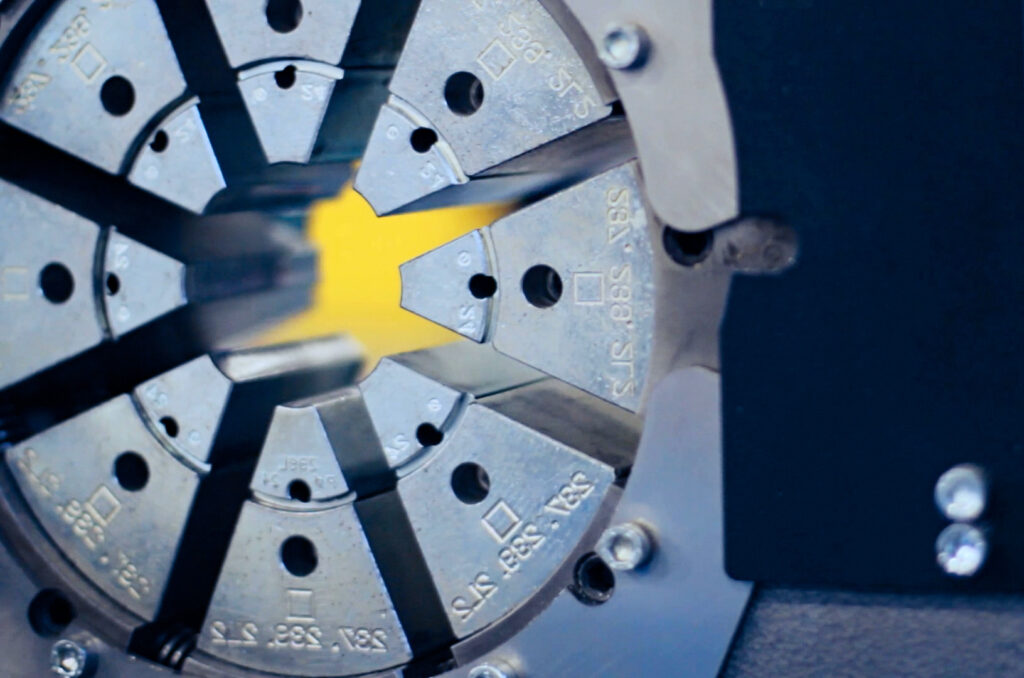

Based at our humble production plant at Serangoon, we are able to perform “in house” all the phases of the production process, from measuring, fitting, cutting and crimping in a controlled atmosphere. All our brake lines were assemble with machine operated hydraulic crimper with specific pressure.

The benefit of braided lines is the durability; over time rubber brake lines become soft so, as they expand under pressure, you lose some of the force that’s applied to the brake pistons; your brakes end up feeling a little spongy and slower to respond.

However the advantages to putting braided lines on a brand new bike that has rubber lines is however minimal – it’s as they start to wear over time that the difference will be felt.